How to Improve Paper Pulp Strength

What is Paper Pulp Strength

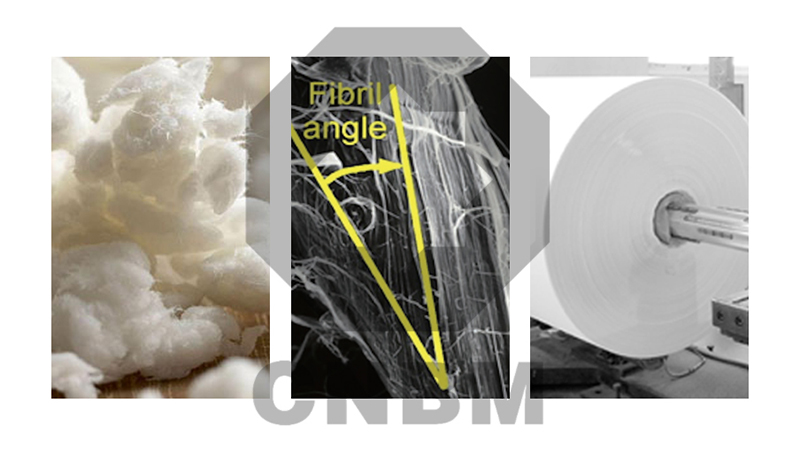

The strength of paper pulp depends on the strength, the distribution and arrangement of fibers in paper pulp. The most important is the strength of the fibers, which determines the mechanical properties of the pulp and paper.

What factors affect paper pulp strength

Paper pulp strength is measured by a number of indicators, including pretreatment PH value, Capa value, tightness, tensile index, tear index, breaking index etc. Paper pulp strength is closely related to the beating and making process in the paper pulping process. The effect of paper pulp beating on fiber, especially the degree of fiber broom, is the main factor affecting fiber binding. Because of that the fiber surface area and hydrogen bond number are related to beating. At the same time, the size of the fiber binding force is related to the chemical composition, physical properties and arrangement of the fibers. In other words, fiber lignin, hemicellulose, cellulose content, etc, will affect the fiber binding to some extent.

Therefore, pulp strength is affected by many factors. Mainly include: pulp types, hemicellulose, cellulose, lignin, paper-making additives, papermaking operation etc.

How to control pulp strength

Selection of paper pulp types

Different kinds of paper pulp are different in physical structure and chemical composition. Generally speaking, chemical wood pulp fiber adhesion is the largest, cotton pulp is the second, mechanical wood pulp is the worst. The first step to improve paper pulp strength is to select better paper pulp types.

Control the effect of hemicellulose

The pulp with high hemicellulose content is easy to absorb water and swell during beating, which increases the specific surface area and binding area of the fiber, and improves the binding force of the fiber. Hemicellulose has shorter molecular chains than cellulose, and is more hydrophilic. When it is beating by the paper pulp beater, it is easy to absorb water and expand and fine fibrosis. Therefore, the pulp containing hemicellulose is easier to beat and the binding force between fibers is larger.

Of course, the high content of hemicellulose is not good for beating and papermaking. The main reason is that the hemicellulose absorbs water and expands too fast, the beating is too high, so the paper is transparent and brittle, and the strength is low. On the other hand, with more hemicellulose and more short fibers, the strength of the fibers will decrease and the adhesion of the fibers will be reduced.

Control the effect of cellulose

In general, cellulose molecular chain is long, it is high degree of polymerization, the fiber itself is strong, when beating by the paper pulp beater, is not easy to cut off. Therefore, when it has already been cut to an appropriate length, the fiber has been fully broomized, and the adhesion between the fibers is greater.

Control the influence of lignin

There was a negative linear correlation between lignin content on pulp fiber surface and tensile index and breaking resistance index. With the increase of lignin content, the tensile index and breaking resistance index of the paper decreased. The blending ratio has no obvious effect on tensile index and breaking index of finished paper, but has certain effect on tear index of pulp tensioning.

Lignin mainly distributes in the primary wall and the secondary wall of the fiber. Because of the very low hydrophilicity of lignin, the existence of lignin affects the swelling and fine fibrosis of the fiber, so the pulp containing more lignin is not easy to beat and the binding force of the fiber is poor.

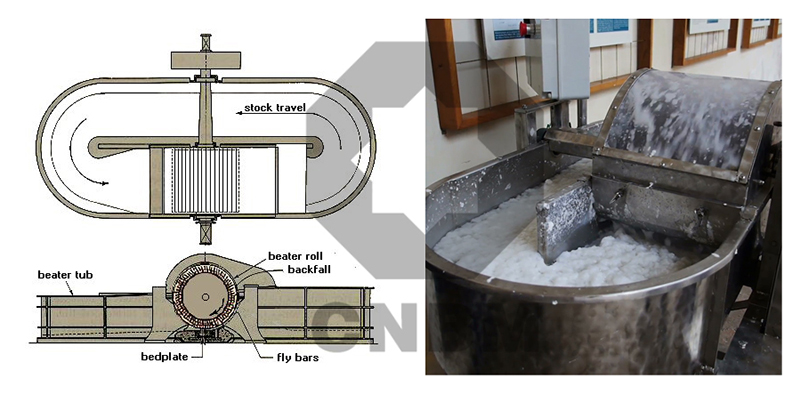

Paper pulp beating must be strictly controlled. Therefore, starting from beating, the beating degree, wet weight and water retention value were measured every certain time, and the changes of fiber morphology were observed. At the same time , the paper should be sampled and the physical strength of pulp should be measured to study the change of pulp performance during paper pulping process.

Control the effect of Papermaking Additives

The addition of hydrophilic substances, such as starch, protein, vegetable gum, etc. Adding things like these to the pulp increases the interfiberal adhesion, because these substances themselves have the same polar hydroxyl groups as cellulose, because the hydroxyl groups bind to hydrogen bonds.The combination of fiber is stronger than that of pure fiber. The addition of hydrophobic substances, such as inorganic fillers and alum, can reduce the adhesion between fibers, which is because the addition of these substances will separate the fibers from the fibers and reduce the interface between the fibers, thus affecting the adhesion of the fibers.

Control the influence of papermaking process

This is the technology work in the paper pulping process, such as beating, such as drying. Because of that paper strength is not only related to fiber itself, but also to paper fiber binding strength. The strength of the bond is related to paper making. In general, the bonding strength between the pulp fibers is proportional to the ability of the fiber to form hydrogen bonds between the fibers.

For the same kind of paper pulp, the fiber's specific surface area and contact area are constant. If lignin is adsorbed on the fiber surface, the ability of forming hydrogen bond between fibers will be affected, which will lead to the decrease of interfiber bonding strength.

Paper pulp beating machine is an important equipment in papermaking process.

It plays an important role in pulp, as well as in the strength of paper products, and needs careful selection. CNBM can introduce to customers about pulp strength, and can provide relevant equipment for beating machines. Please contact us for details of the type of paper pulper machine. Welcome to consult!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.