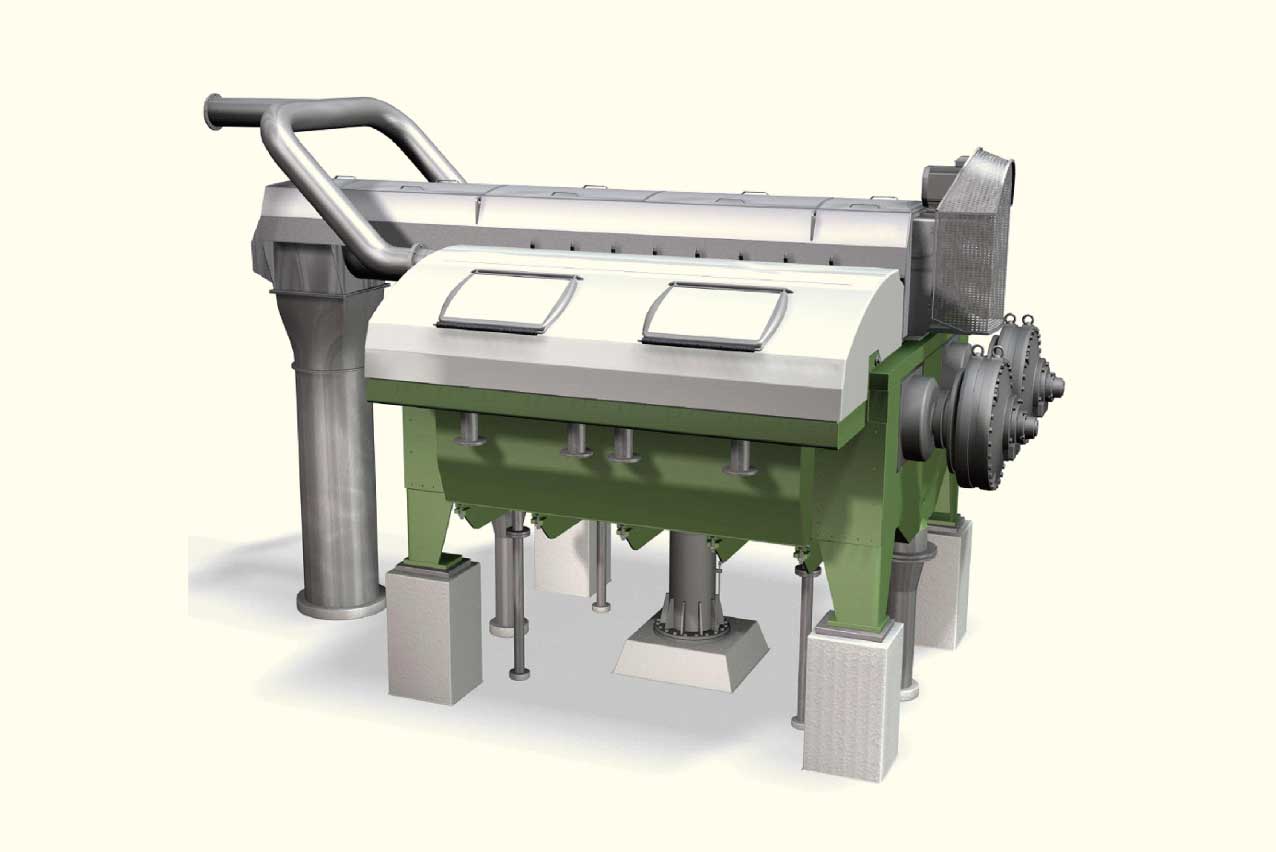

twin roll press

- Set dehydration, displacement, press in one, washing effect is better.

- Equipped with advanced hydraulic drive system, stable and reliable operation.

- Adopt press principle, no vacuum requirement, realize different height installation, save the investment of factory building.

Twin roll press adopts displacement pressing principle to achieve continuous dehydration and washing of paper pulp. It is a kind of black liquor extraction and bleaching equipment with advanced function and high technology in the world. It is suitable for chemical pulp, chemical-mechanic pulp and waste paper pulp. The performance of this product is reliable, the operation index reaches the international advanced level, and it can equipped with project that the annual output of which is 10 ~ 1.5 million tons.

Twin roll press we offer

The equipment can be operated on a single machine and can be combined with multiple paper pulper machines for the treatment of large production scale paper pulp for paper making industry.

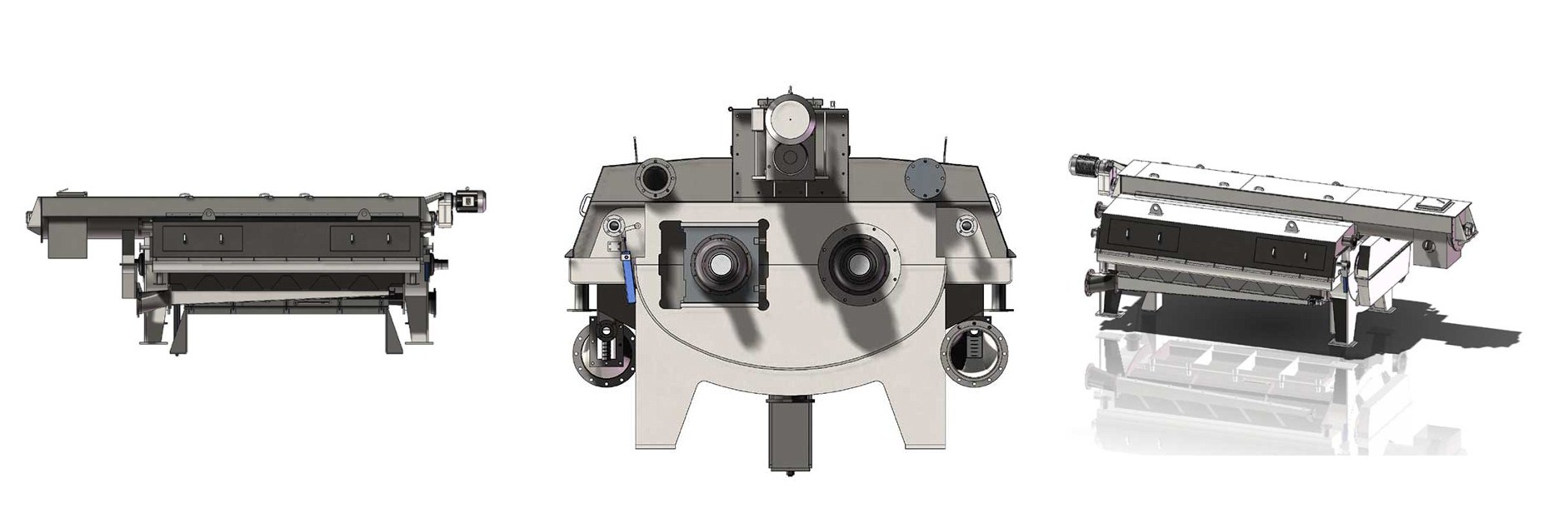

| Model /Item | Drum length (mm) | Drum Dia. (mm) | Drum Speed (rpm) | Feed Consistency(%) | Discharge Consistency (%) | Production Capacity | ||

|---|---|---|---|---|---|---|---|---|

| Straw / Bagasse pulp | Bamboo pulp | Wood pulp | ||||||

| AMSG712 | 1200 | 700 | 2~20 | 3.5~10 | 20~35 | 30~40 | 60~80 | 80~100 |

| AMSG915 | 1550 | 900 | 2~15 | 3.5~10 | 20~35 | 40~60 | 85~120 | 130~160 |

| AMSG920 | 2000 | 900 | 2~15 | 3.5~10 | 20~35 | 55~85 | 125~160 | 175~210 |

| AMSG928 | 2820 | 900 | 2~15 | 3.5~10 | 20~35 | 80~120 | 165~220 | 250~300 |

| AMSG935 | 3500 | 900 | 2~15 | 3.5~10 | 20~35 | 110~150 | 225~280 | 310~370 |

| AMSG940 | 4000 | 900 | 2~15 | 3.5~10 | 20~35 | 120~170 | 220~310 | 350~400 |

| AMSG945 | 4500 | 900 | 2~15 | 3.5~10 | 20~35 | 160~180 | 285~350 | 400~480 |

| AMSG1532 | 3200 | 1500 | 2~15 | 3.5~10 | 20~35 | 220~350 | 450~600 | 700~800 |

| AMSG1540 | 4000 | 1500 | 2~15 | 3.5~10 | 20~35 | 400~550 | 800~1000 | 1200~1500 |

| AMSG1550 | 5000 | 1500 | 2~15 | 3.5~10 | 20~35 | 500~650 | 1000~1300 | 1700~1800 |

| AMSG1572 | 7200 | 1500 | 2~15 | 3.5~10 | 20~35 | 750~1000 | 1500~1800 | 2500~3000 |

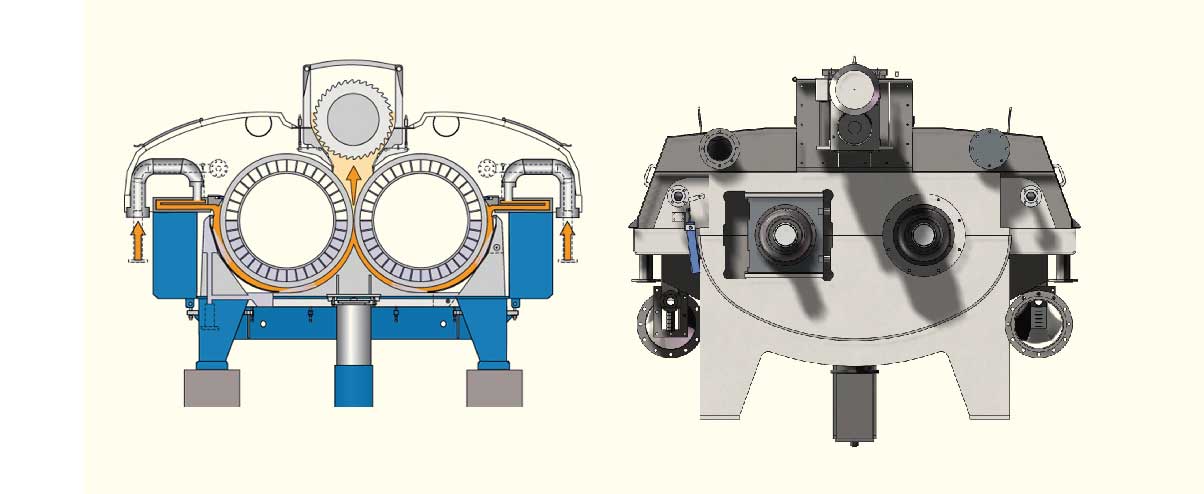

Twin roll press working principle

At a certain pressure, the pulp with low concentration is fed into a closed pulp slot by a screw conveyor. A pair of groove pressure rollers are built in the pulp groove, and a series of groove cracks are arranged on the surface of the pressure roll, which passes through the axial holes through the roll body and is discharged from the end of the roller. In order to prevent the clogging of the gully, a group of thinning knives were inserted into the crevice, and the axial hole entered into the water or dilute black liquor under certain pressure from the axial hole to dredge and clean the groove and drain hole. The pulp is squeezed to a high concentration and then peeled into the pulp pool by the scraper.

Twin roll press advantages

- Set dehydration, displacement, press in one, washing effect is better.

- With independent intellectual property rights of the pulping device, CNBM can achieve a more perfect pulp distribution effect.

- Equipped with advanced hydraulic drive system, stable and reliable operation.

- Adopt press principle, no vacuum requirement, realize different height installation, save the investment of factory building.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.