chemi-mechanical pulping process

Chemi-machanical pulp called CMP for short. There are semi chemical methods, chemical mechanical method and chemical hot grinding machine method in chemical mechanical pulping. In addition to the chemical or mechanical methods mentioned above, the pulp manufacturing process uses a combination of these two methods to dissociate the fibers from materials and then purify or refine them into raw pulp or bleached pulp.

Chemi-mechanical pulp category

Paper pulp can be classified according to the type of raw material, paper pulping process and pulp yield. Chemi-mechanical pulp aka CMP, including APMP, P-RC APMP. The yield of chemical-mechanical pulp is 65-94.

Chemi-mechanical pulp pulping process

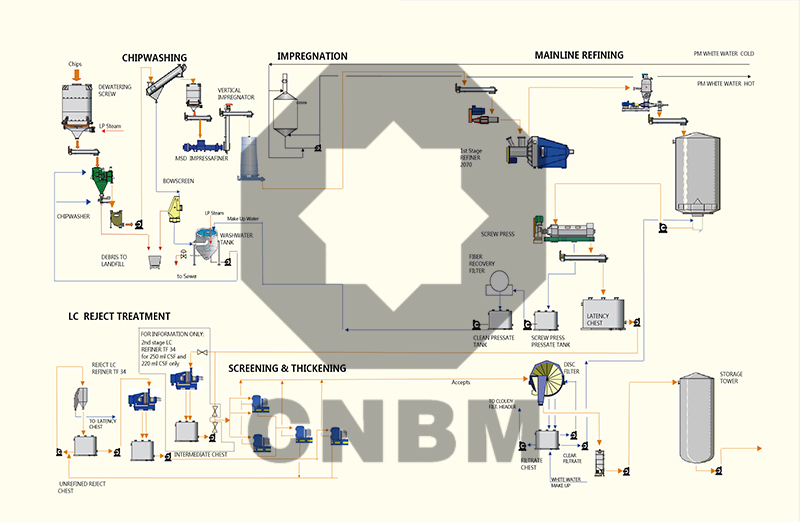

The following figure is the process flow chart of APMP.

The raw materials from the preparation area are washed and presteamed by scrubbers, and then sent by the conveying equipment to the stage of extrusion and impregnation through the screw press and the chemical pre-impregnation, and the resulting paper pulp is transported to the second stage of impregnation.The impregnated paper pulp is delivered to the two-stage disc mill, the final paper pulp of the paper pulp separator reaches the intermediate pool, and the finished paper pulp is finally formed after the process of squeezing dehydration and secondary grinding and screening.

Chemi-mechanical pulp features and applications

The chemical treatment conditions were mild and more lignin was retained in the pulp. The yield of pure pulp can be as high as 85 / 90. The properties of chemical and mechanical pulp made of /poad-leaved wood are similar to those of coniferous wood pulp, the paper is compact, the opacity is low, the content of long fiber is more, the fiber bundles are few, and the printability is good. Chemi-machanical pulp can be made into newsprint, printing paper, paperboard, etc.

CNBM can design and engineer the chemi-mechanical pulp production line according to your requirement and we can also provide all the paper pulping machine needed in a chemi-mechanical processing system including digester, blow tank, replacement tank, heat exchanger, all kinds of supporting tank like cold and hot black liquor tank, cold and hot white tank, etc. and other auxiliary valves etc. Our professional engineer can make customized plan for you and meet your process demands and local environment protection standards precisely. Please leave us messages below to get a quote and more details. Contact us, today!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.