continuous digester

- Good fluid mixing uniformity, especially suitable for solid-liquid three phase coexistence of oxygen alkali cooking process.

- The consumption of steam in the cooking can be greatly reduced, and the amount of black liquor in the extraction section can be greatly reduced. Reduce the burden of black liquor evaporation section.

- Low cost of the factory building and low power consumption.

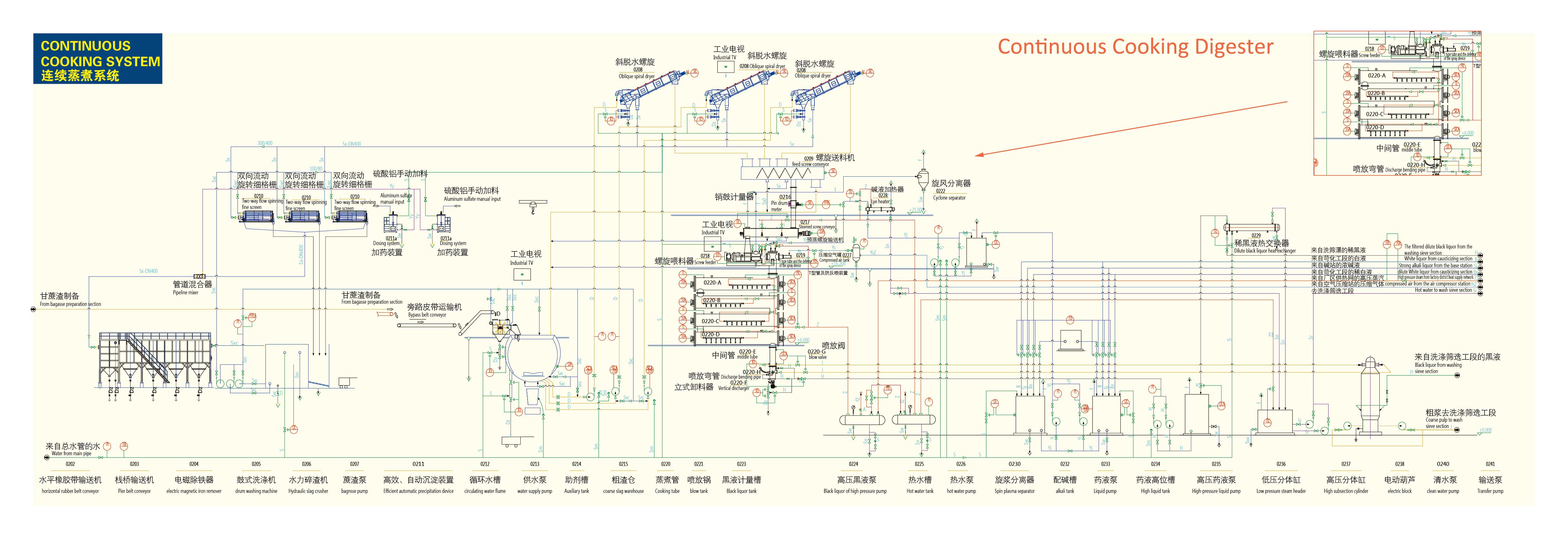

Horizontal tube continuous digester now, through development, can be used to process various raw materials. It can be used for cooking and bleaching sulphate wood pulp. Pulp material is mainly broadleaf wood, also can be straw, wheat straw, bagasse, reed and other grass materials. Horizontal tube continuous digester is mainly composed of cylinder, end cover, screw shaft, bearing, saddle, feeding tube, discharge pipe, steam pipe, standby exhaust pipe, instrument interface, maintenance (observed) hole, transmission device and other parts.

Pulp cooking Continuous digesters we offer

Continuous cooking can shorten the whole cooking time greatly.The horizontal continuous digester has the feature of high yield, uniform quality and stable performance.The continuous digester contains a group of horizontal tubes arranged in parallel. There are various types of continuous digesters acoording to the amount of the tubes. It can be 2 tubes,4 tubes, 6 tubes, and 8 tubes etc. There is a screw propeller in the tube. These propellers has different RPM, so they are more and more slow form the top to the bottom.

Continuous digester working principal

The fibrous material is fed into the first digester by a helical feeder. It is then driven and stirred by the spiral blades, mixed well with the liquid in the process of its slow motion. At the same time, the pressure steam is heated or kept warm in the steam boiling tube. At a certain temperature, according to the process predetermined pulping reaction time, the materials go through the root cooking tube in turn until the last pipe, after they go out of the outlet, the soaking and cooking process is complete.

Continuous digester advantages

- Good fluid mixing uniformity, especially suitable for solid-liquid three phase coexistence of oxygen alkali cooking process.

- The cooking liquor ratio is adjustable, even if it is a small liquid ratio, it will not produce the phenomenon of uneven cooking. In this way, the consumption of steam in the cooking can be greatly reduced, and the amount of black liquor in the extraction section can be greatly reduced Reduce the burden of black liquor evaporation section.

- Low cost of the factory building, as the horizontal installation of the pot system, and without more than one pot in series, it can greatly reduce plant height and cost.

- Low power consumption, the system does not require more than one pot body in series, so that it can greatly reduce the conveying height of raw materials, reduce the energy consumption of the piece of conveying, two can reduce the power consumption of pot pushing material.

- The installation and operation are convenient, in particular, can reduce the number of operators.

- The system structure is relatively simple, the system maintenance and repair costs low.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.