apmp production line

- 12 m³ 70℃-90℃ pulp level ≥70% (control time).

- 12 m³ 80℃-90℃ pulp level ≥70%.

- High yield, high brightness, high strength and low pollution, low water consumption, low energy consumption and low material consumption.

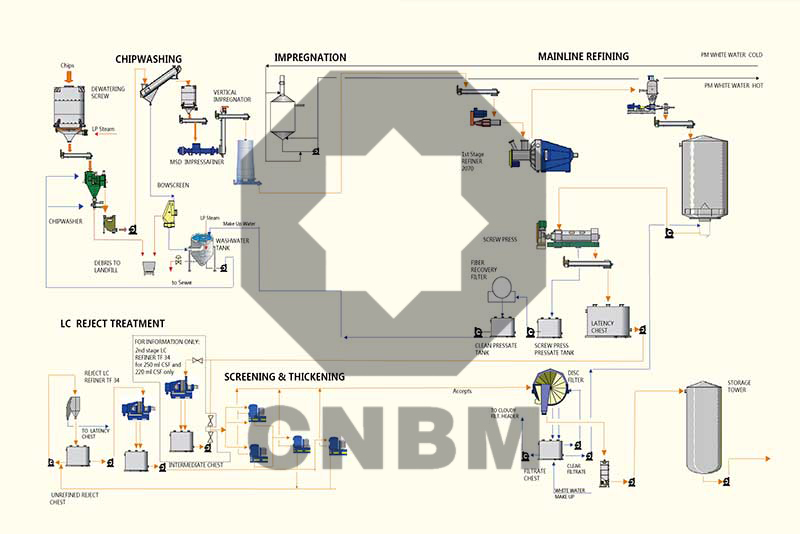

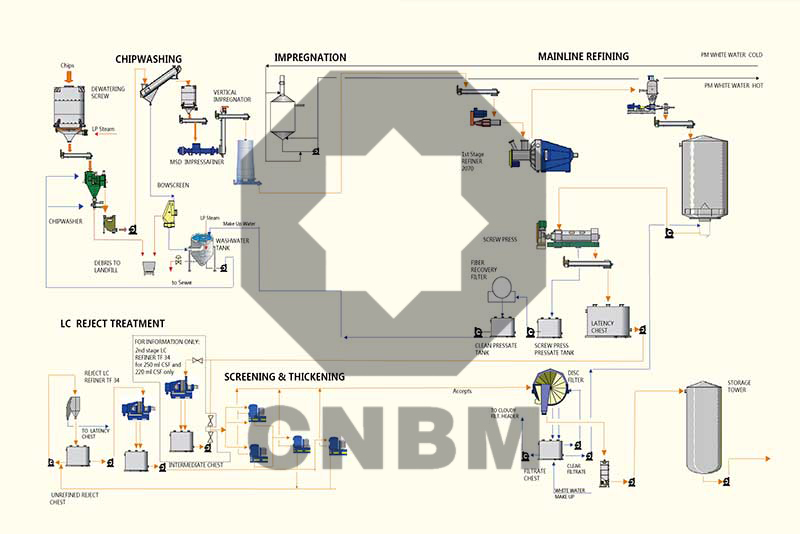

On the basis of BCTMP, the APMP paper pulping process was developed in 1989 by ASB company, namely Alkaline Peroxide Mechanical Pulp. APMP paper pulping process has the outstanding advantages of super high yield, good pulp strength, less pollution and low energy consumption. It breaks the traditional concept of paper pulp making and finishes cooking and bleaching simultaneously in a single chemical pretreatment process, which greatly simplifies the paper pulping process, reduces investment costs by 25% or more.

APMP paper pulping process we offer

- 12 m³ 70℃-90℃ pulp level ≥70% (control time).

- 12 m³ 80℃-90℃ pulp level ≥70%.

- Reaction tank: 10m³ 15min t≥90℃.

- Impregnator: Adding chemicals to the impregnator, mainly Naoh, H2O2 and hydrogen peroxide stabilizers such as DTPA (or EDTA), sodium silicate, magnesium salts.

- Refiner: APMP paper pulping process is atmospheric refining, atmospheric pressure grinding its grinding zone pressure is lower, in order to reduce the ineffective decomposition of H2O2, to improve the whiteness of pulp advantage.

- Latency Chest: Intermediate Chest .

- High Concentrate bleaching Tank.

- Heat recovery equipment: atmospheric scrubber and pressure scrubber.

- Condensing equipment: Disc filter.

- Conveying screw: various series specifications and diameters conveying screw, according to different paper pulp processing equipment, material of spiral conveyer, mainly including carbon steel and stainless steel.

APMP paper pulping process working principle

APMP paper pulping process mechanism:

-

Alkali swelling fiber.

At the end of the first prepreg, the pulp yield decreased more and the whiteness decreased. -

H2O2 bleaching.

At the end of the second stage of prepreg, the pulp yield decreased steadily and the whiteness increased sharply, which was mainly due to the high content of H2O2, which played the role of bleaching. -

The chemical reaction of the pulp process.

After grinding, the pulp yield decreased slightly, and the brightness of pulp increased greatly. -

The content of lignin molecule increased and the chromogenic group decreased.

After pulping, the average molecular weight of lignin in pulp increased, and H2O2 destroyed the chromogenic groups such as phenolic hydroxyl group and o-phenol structure in lignin, and increased the whiteness of lignin.

APMP paper pulping process advantages

As a new energy-saving and environment-friendly pulping technology, APMP paper pulping process has the outstanding advantages of high yield, high brightness, high strength and low pollution, low water consumption, low energy consumption and low material consumption, etc. It is praised as the best pulping technology in this century.

Since the development of APMP paper pulping process technology, it has been attracting the attention of the world paper pulp making and paper making industry. This paper and pulp technology has been adopted by many developed countries in the world. At present, the focus of foreign research is mainly wood fiber pulping, and in the application of poplar, according to wood, spruce, pine wood and other pulp mix newsprint and cultural paper has achieved success. The study of non-woody fibers is still in its infancy. Andritzan, Springfield, Canada's Hymac, and others own the paper and pulp technology.

APMP paper pulping process has been widely used in developed countries and has become its main paper and pulp technology and paper pulp machines. Research on the technology's wider applicability to various raw materials has never stopped. Most of the developing countries have also begun to introduce and apply this advanced technology and equipment to pulping. The development potential of APMP paper pulping process in the world market is huge.

CNBM is one of the leading paper pulp machine manufacturers in the field of paper pulp machinery. Our company's leading products include large chemical containers, tower, reactor, heat exchanger, complete pulping production line, intermittent cooking equipment, large-scale chemical pulp production line, complete set of pulping equipment APMP paper pulping process, multi-disc vacuum filter and other complete sets of paper pulp machines. Welcome friends from all over the world to contact us!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.