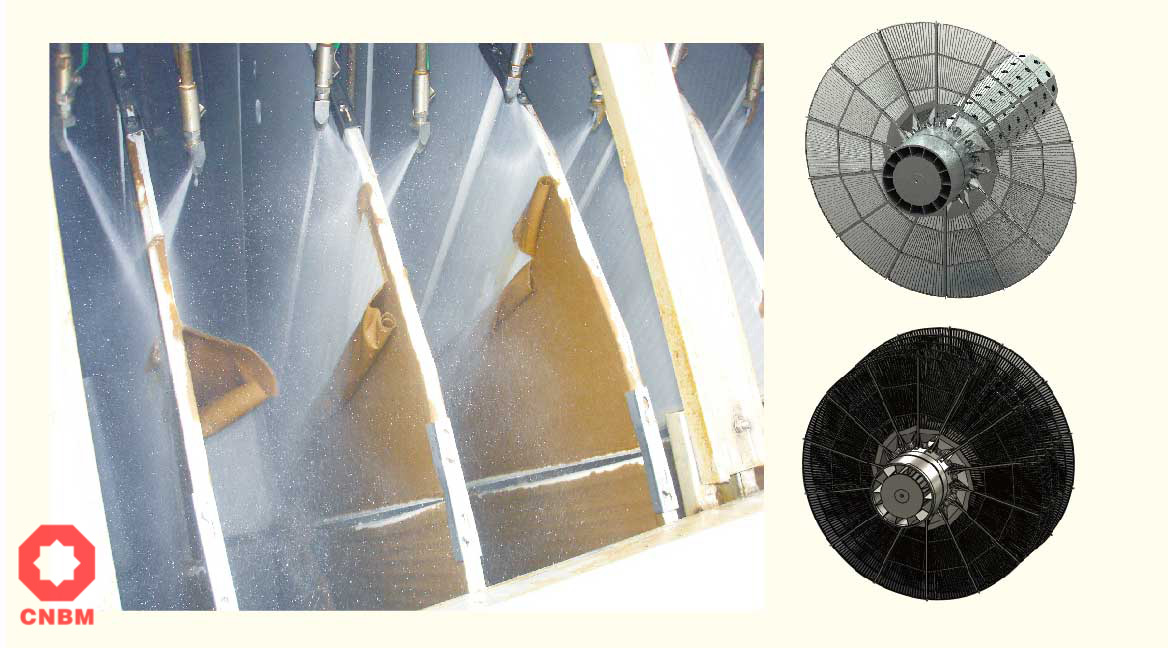

disc filter

- Save energy and water resources, reduce fiber loss, achieve environmental protection and avoid pollution.

- Can adjust the pulp density and processing capacity according to the customers' technical requirements. CNBM has advanced design software and mature technology, has a market share of over 70% in China.

- When the pulp is concentrated, the pulp concentration is high, which can reach 10-14%.

Disc filter is a paper pulping equipment of new generation. It is mainly used for white liquor recovery and pulp refining. Disc filter can save energy and water resources, reduce fiber loss, achieve environmental protection and avoid pollution. Disc filter is mainly used in the recycling of white liquor during the process of papermaking, and the pulp refining in the pulping process.

Disc filter we offer

CNBM disc filter can adjust the pulp density and processing capacity according to the customers' technical requirements. CNBM has advanced design software and mature technology. CNBM disc filter has a market share of over 70% in China.

Disc filter series and specifications:

| Disc QTY | ZNH25 | ZNH35 | ZNH45 | ZNH44 |

|---|---|---|---|---|

| Overall dimension L*W*H(mm) | Overall dimension L*W*H(mm) | Overall dimension L*W*H(mm) | Overall dimension L*W*H(mm) | |

| 4 | 3885*3035*4168 | |||

| 6 | 4485*3035*4168 | |||

| 8 | 5085*3035*4168 | 5510*4100*5361 | 6319*5450*6060 | |

| 10 | 5685*3035*4168 | 6210*4100*5361 | 7019*5450*6060 | 7415*6400*7235 |

| 12 | 6285*3035*4168 | 6910*4100*5361 | 7719*5450*6060 | 8115*6400*7235 |

| 14 | 6885*3035*4168 | 7610*4100*5361 | 8419*5450*6060 | 8815*6400*7235 |

| 16 | 8310*4100*5361 | 9119*5450*6060 | 9515*6400*7235 | |

| 18 | 9010*4100*5361 | 9819*5450*6060 | 10215*6400*7235 | |

| 20 | 10915*6400*7235 | |||

| 22 | 11615*6400*7235 | |||

| 24 | 12315*6400*7235 |

| Item | ZNH25 | ZNH35 | ZNH45 | ZNH55 |

|---|---|---|---|---|

| Model | ||||

| Disc Dia. (mm) | 2500 | 3500 | 4500 | 5500 |

| Per-disc filtration area (m2) | 8.5 | 16.7 | 26 | 38 |

| Capacity |

0.6-3M3/m3.h (white water recovery) 0.7-1.5t/m3.d (pulp thickened) |

|||

| Fiber recovery rate (%) | >95 | |||

| Filtrate clarity(mg/L) | 20-80 | |||

| Inlet consistency (%) |

0.2-0.6(white water recovery) 0.5-1.2 (Pulp thickened) |

|||

| Outlet consistency (%) |

4-6(white water recovery) 4-15 (Pulp thickened) |

|||

| MOC | SS304 material for parts in contact with product | |||

| Vacuum degree (Mpa) | 0.02-0.06 | |||

| Net washing water pressure (Mpa) | 0.7 | |||

| Stripping water pressure (Mpa) | 0.7 | |||

Disc filter working principle

The white liquor enters the disc filter through the feeding box and distributes evenly throughout the tank. Under the action of gravity, the pulp layer (2-3mm) is formed on the fan. In order to ensure the optimal dewatering, the filtrate is discharged to the corresponding filtrate channel in the central axis through the fan with open grille.

The rotating shaft is connected to a filtrate valve that can switch the relevant vacuum channel. A vacuum is formed by the loss of atmospheric water. When the filtrate enters the filtrate valve, it is divided into turbid filtrate, clear filtrate and ultra clear filtrate.

When the fan body emerges from the suspension, the filtrate is expelled, and the pulp layer is dehydrated under vacuum. The pulp is stripped from the fan body by a spray pipe, which is then placed side by side into the discharge channel in the tank, and then to the spiral conveyor. The filter screen is washed clean by the vibrating water pipe before the next cycle begins.

Disc filter advantages

- In the process of white liquor recovery, water recycling is realized and water consumption is reduced. The fiber recovery rate is high, eliminating waste and pollution when white liquor is discharged.

- When the pulp is concentrated, the pulp concentration is high, which can reach 10-14%.

- The filter plate features diversified structure, economical application, high strength, convenient replacement, large effective filtration area and good filtering effect.

- The equipment model specification is complete, can change the filter area according to different production requirement.

- Special wear-resistant material distribution plate, good sealing effect.

- High degree of automation, easy to operate, reliable performance.

- Compact structure, small footprint, large production capacity.

- Good economic and social benefits.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.

gravity disc filter

gravity disc filter