chemical pulping process

Chemical pulp is a type of paper pulp. It is the kind of pulp that dissolve plant fiber by chemical method. The raw materials for making chemical paper pulp are plant fiber. People use chemical agent that can start selective chemical reaction with the lignin in the raw materials. In this way, most of the lignin will be dissolved and separated temporarily. And the single fiber cell can be fully separated. The yield of chemical pulp is between 40%-65%.

Chemical pulp category

According to the chemical methods, chemical pulp can be divided to alkaline pulp, sulfate pulp, sulfite pulp, neutral sulfite pulp and chlorinated pulp etc. According to the raw material, chemical pulp can be divided into chemical wood pulp, chemical hemo pulp, chemical straw pulp, chemical bamboo pulp, chemical bagasse pulp, chemical cotton pulp and chemical reed pulp.

Chemical pulping process

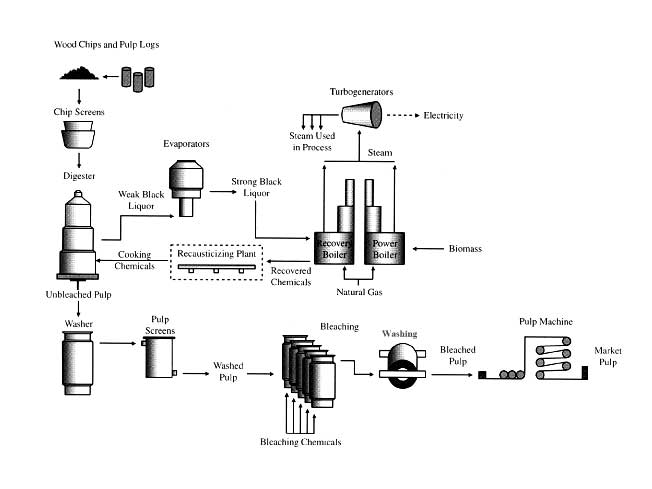

The specific chemical pulp production process is shown in the picture below:

The sheets is transported from the reparation workshop to the paper pulp cooking equipment by the conveyor. The sheets is cooked in the digester with chemical agent under the temperature of 160 ℃. After the digestion, we can get unbleached coarse pulp. At the same time, the black liquid which is generated in the cooking process will go through the black liquid evaporating equipment and changed into strong black liquid. The heat generated will be recycled by the heat recovery equipment. And the unbleached coarse pulp will be blown, then transported to the washing and bleaching process by the conveyor. The washed pulp will be screened then go into the bleach process. According to the whiteness needed, the pulp will be added into chemical agent to get bleached. After bleaching ,the pulp will be washed again, then the chemical bleached pulp is ready to go into the next process, paper making or pulp board making. Generally speaking, the pulp will go into the pulp board machine, and be made into goods pulp board.

Chemical pulp features and applications

In accordance with the raw material and the pulping method, pulp in different quality can be used in different ways. For instance, sulfite pulp is clean and soft, and easy to get bleached. It can be used to make advanced writing paper and printing paper. The sulfate pulp has long and strong fiber, can be used to make industrial and technical paper.

Bleached chemical pulp is mainly used to make advanced printing paper, copy paper, computer paper, offset paper, cover paper, writing paper and paper bag paper etc. The unbleached chemical pulp can be used to make high-strength industrial paper such as kraft paper and paper bag paper etc.

CNBM can design and engineer the chemical production line according to your requirement and we can also provide all the paper pulping machine needed in a chemical processing system including digester, blow tank, replacement tank, heat exchanger, all kinds of supporting tank like cold and hot black liquor tank, cold and hot white tank, etc. and other auxiliary valves etc. Our professional engineer can make customized plan for you and meet your process demands and local environment protection standards precisely. Please leave us messages below to get a quote and more details. Contact us, today!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.