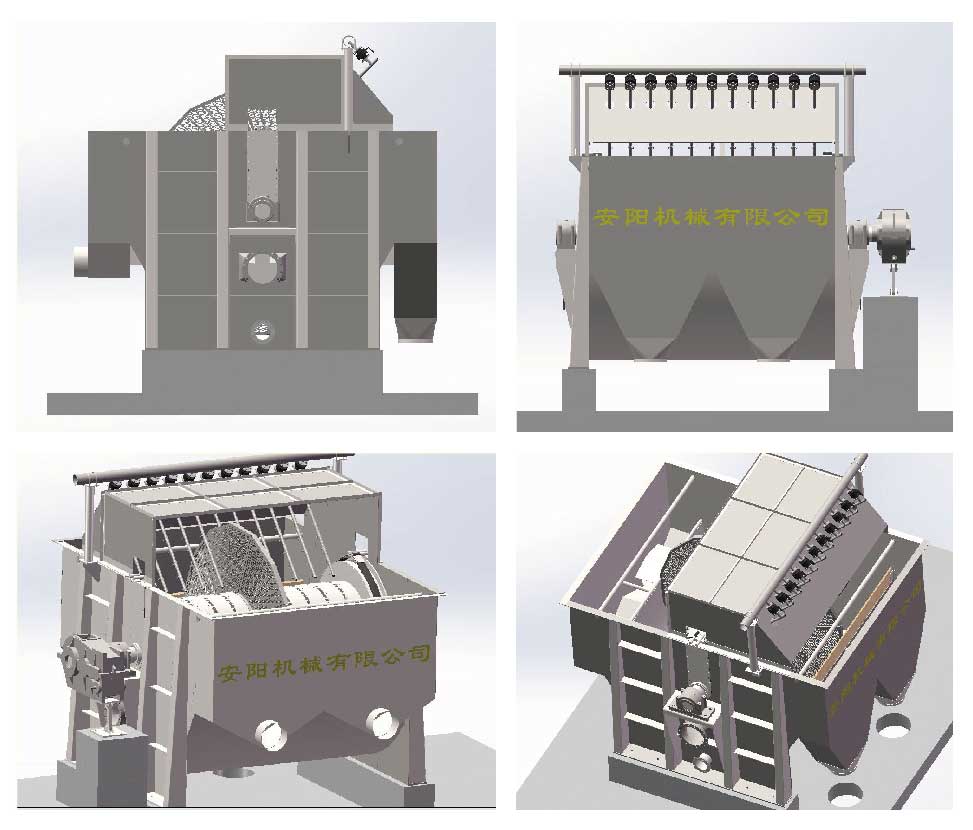

gravity disc filter

- Unlike the traditional vacuum disc filter, it can replace the traditional gravity filter without the installation height of the water log.

- Applicable to shorter fiber or higher consistency of mechanical wood pulp, waste pulp, reed pulp, bagasse pulp and straw pulp with low freeness (higher beating degree).

- High degree of automation, easy operation, reliable function, high production capacity, low power consumption and convenient management.

Gravity disk filter is mainly used to concentrate low concentration paper pulp. Unlike the traditional vacuum disc filter, it can replace the traditional gravity filter without the installation height of the water log. The installation of gravity disc filter is more convenient, and the installation height of water log is not required. It can be applied to the treatment of various raw materials, including wood pulp, straw pulp and waste paper pulp.

Gravity disc filter we offer

CNBM gravity disc filter is mainly used for low consistency stock thickening. Different from traditional vacuum disc filter, the water log installation height is not needed. It can replace traditional gravity decker thickener.

Gravity disc filter technical parameters

| Model | ZNP26 | ZNP35 |

|---|---|---|

| Item | ||

| Dia. (mm) | 2600 | 3500 |

| Per-disc filtration area (m2) | 7.5 | 15 |

| Capacity | 0.8—3t/M2.d | |

| Inflow consistency (%) | 0.3-2 | 0.3-2 |

| Outflow consistency (%) | 3~5 | 3~5 |

| Washing pressure for sieve cleaning (Mpa) | 0.6-0.7 | |

| Disc QTY | ZNH26 | ZNH35 |

|---|---|---|

|

Overall dimension L*W*H(mm) |

Overall dimension L*W*H(mm) |

|

| 6 | 3718*4035*3230 | |

| 7 | 3998*4035*3230 | |

| 8 | 4278*4035*3230 | 4705*5090*4383 |

| 9 | 4558*4035*3230 | 5005*5090*4383 |

| 10 | 4838*4035*3230 | 5305*5090*4383 |

| 11 | 5118*4035*3230 | 5605*5090*4383 |

| 12 | 5398*4035*3230 | 5905*5090*4383 |

| 13 | 5678*4035*3230 | 6205*5090*4383 |

| 14 | 5958*4035*3230 | 6505*5090*4383 |

| 15 | 6238*4035*3230 | 6852*5090*4383 |

| 16 | 6518*4035*3230 | 7152*5090*4383 |

| 17 | 6798*4035*3230 | 7452*5090*4383 |

| 18 | 7078*4035*3230 | 7752*5090*4383 |

| 19 | 8052*5090*4383 | |

| 20 | 8352*5090*4383 |

Gravity disc filter working principle

The gravity disk filter is composed of a sector and a tank. The paper pulp flows into the tank through the stock inlet, then continuously gathering on both sides of thesector. The disc rotates and brings the pulp up onto the wire side, by high pressure water washing, the paper pulp on the disc peel off, and the filtrate flows through the guide ditch into the shaft of the disc, then discharging. With the rotating of the disc and the discharge of the filtrate, the consistency of paper pulp increases. When the liquid level is higher than the level adjustment plate, the pulp will flow into the tank. In this way, the paper pulp is concentrated.

Gravity disc filter advantages

- Applicable to shorter fiber or higher consistency of mechanical wood pulp, waste pulp, reed pulp, bagasse pulp and straw pulp with low freeness (higher beating degree).

- High degree of automation, easy operation, reliable function, high production capacity, low power consumption and convenient management.

- Filtration materials include stainless steel structure or polyester fabric.

- The sector is welded by stainless steel, which is convenient to be installed and removed. It can filter the fine fibers, chemical drugs, and fillers in the paper pulp.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.