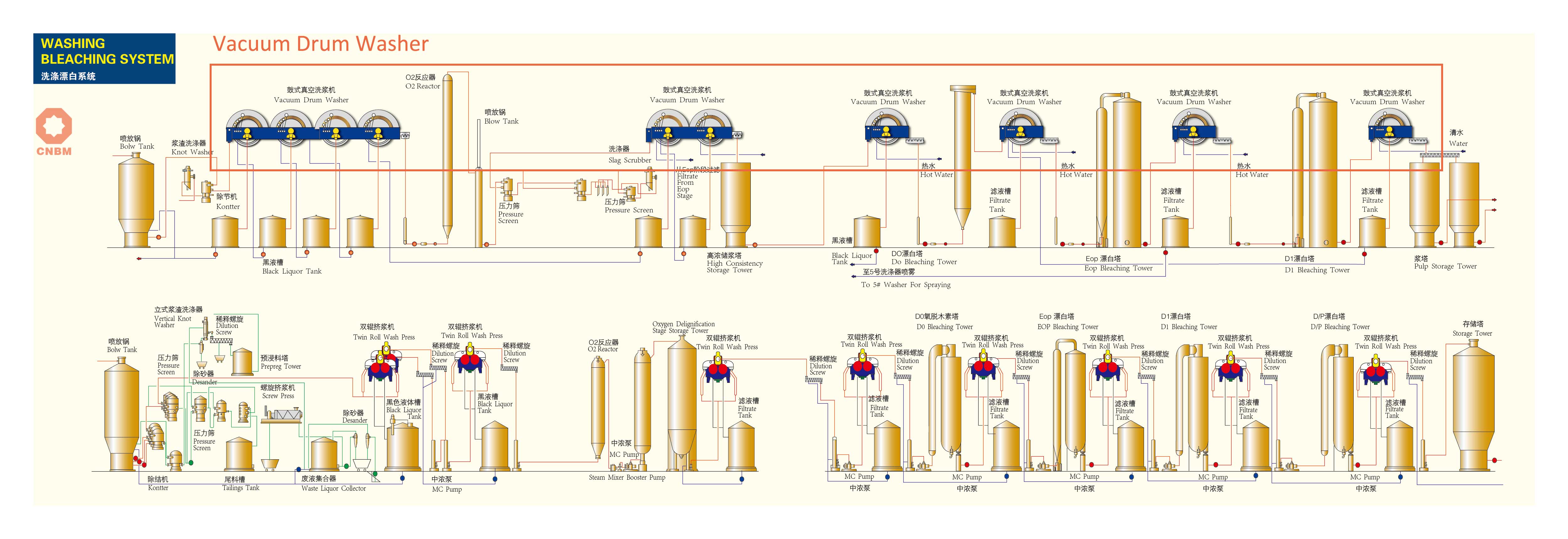

vacuum drum washer

- High productive capacity per area.

- The plane valve core adopts multi-point fixed technology, the operation gap is not changeable, the vacuum degree is stable.

- Corrugated filter board can increase the effective filtration area. It is anti-pouring and not easy to "paste the net".

Vacuum drum washer is a common pulp washing equipment. It is suitable for washing all kinds of paper pulp such as wood pulp, straw pulp and reed pulp etc. Vacuum drum washer is also a key equipment for paper and pulp industry to solve the problems of waste water pollution and the alkali recovery. Vacuum drum washer can be used alone or in series.

Vacuum drum washer we offer

| Model /Item | Drum length (mm) | Drum Dia. (mm) | Drum speed (rpm) | Feed Consistency(%) | Discharge Consistency (%) | Capacity( black liquor extraction)(Kt/m2.d) | ||

|---|---|---|---|---|---|---|---|---|

| Straw /Bagasse pulp | Bamboo pulp | Wood pulp | ||||||

| AMXJ35 | 3200 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 52.5~87.5 | 175~210 | 210~280 |

| AMXJ40 | 3650 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 60~100 | 200~240 | 240~320 |

| AMXJ45 | 4100 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 67.5~112 | 225~270 | 270~360 |

| AMXJ50 | 4550 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 75~125 | 250~300 | 300~400 |

| AMXJ55 | 5000 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 82~137.5 | 275~330 | 330~440 |

| AMXJ60 | 5450 | 3500 | 0.8~3 | 1.5~2.5 | 8~12 | 90~150 | 300~360 | 360~480 |

| AMXJ65 | 5200 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 98~162.5 | 325~390 | 390~520 |

| AMXJ70 | 5600 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 105~175 | 350~420 | 420~560 |

| AMXJ75 | 6000 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 113~187.5 | 375~450 | 450~600 |

| AMXJ80 | 6400 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 120~200 | 400~480 | 480~640 |

| AMXJ85 | 6800 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 127~212.5 | 425~510 | 510~680 |

| AMXJ90 | 7200 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 135~225 | 450~540 | 540~720 |

| AMXJ95 | 7600 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 143~237.5 | 475~570 | 570~760 |

| AMXJ100 | 8000 | 4000 | 0.8~3 | 1.5~2.5 | 8~12 | 150~250 | 500~600 | 600~800 |

| AMXJ105 | 7450 | 4500 | 0.8~3 | 1.5~2.5 | 8~12 | 157~262.5 | 252~630 | 630~840 |

| AMXJ110 | 7800 | 4500 | 0.8~3 | 1.5~2.5 | 8~12 | 165~275 | 550~660 | 660~880 |

| AMXJ115 | 8150 | 4500 | 0.8~3 | 1.5~2.5 | 8~12 | 173~287.5 | 575~690 | 690~920 |

| AMXJ120 | 8500 | 4500 | 0.8~3 | 1.5~2.5 | 8~12 | 180~300 | 600~720 | 720~960 |

Vacuum drum washer working principal

Vacuum drum washer is divided into a number of rooms, each room is related with the the seat corresponding room through the lattice filtrate port, the whole end face can be divided into the vacuum area, pulp peel area and exhaust area by the valve core.

The drum turning in the tank with the pulp. Each turn of the drum, the pulp flows out of the drain hole through the vacuum filter area, the pulp peeling area, and the exhaust zone. Due to vacuum suction, the liquid in the pulp flows out of the filtrate flow channel and is drained by the distribution valve. The pulp is adsorbed on the outside surface of the drum.This is the filtration, pulp peeling and exhaust process.

Vacuum drum washer advantages

CNBM vacuum drum washer features mature technology, stable running, simple operation and good performance.

- High productive capacity per area.

- The drum body adopts the conical flow technique to increase the flow rate, the flow of filtrate and improve the production capacity.

- The plane valve core adopts multi-point fixed technology, the operation gap is not changeable, the vacuum degree is stable.

- The planar distribution valve covers a small area with compact structure and convenient maintenance.

- Corrugated filter board can increase the effective filtration area. It is anti-pouring and not easy to "paste the net".

- The dispersive press and stirring technology are good for mixing the pulp and improving the washing effect.

- Compound side board, overflow weir feed, separated seal structure, improve operation stability, convenient maintenance.

- Driving is mainly regulated by frequency converter, reduces power consumption.

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.