What is chemical paper pulp and its process

What is chemical pulp?

Chemical pulp, a kind of paper pulp, is the general name of paper pulp obtained from dissociated plant fibers by chemical methods. The essence of chemical paper pulp making is to dissolve as much lignin in the intercellular layer and cell wall as possible through the reaction between the chemical solution and the plant fiber at high temperature. The raw material is dissociated into paper pulp.

Main methods: alkali method and sulfite method. The main methods used in the modern paper and pulp industry generally include: alkali method [alkali lime method, caustic soda (caustic soda + AQ), sulfate, oxygen alkali, soda ash, sodium polysulfide method]; sulfite (acid sulfite, sodium bisulfite method, neutral sulfite, alkali sulfite etc.).

According to the raw materials used in paper pulping process, paper pulp can also be divided into chemical wood pulp, hemp pulp, straw pulp, bamboo pulp, cane pulp, cotton pulp, reed pulp and so on.

Pulp and paper chemicals

According to the different methods used to make chemical paper pulp, the chemicals to be used in chemical pulp process are also different. Here are some of the main chemicals used in chemical paper pulping process.

-

Composition of liquid solution of Alkaline Pulp: NaOH + a small amount of Na2CO3

Na2CO3 +Ca(OH)2 «2NaOH+Ca CO3 -

The composition of Kraft pulp : NaOH+Na2, and contains a small amount of component: Na2CO3, NaSO3, Na2Sn, Na2SO4, Na2S2O3

NaOH+Na2SO3+a small amount of Na2CO3, the pH value of which is 10-13. - The composition of the solution of hydrogen sulfite pulp is: MgHSO3 or NaHSO3, and its pH value is 4.

- The composition of the solution of magnesium bisulfite and magnesium sulfite pulping is: MgHSO3 (2) and MgSO3 (pH = 6).

- The composition of solution of acidic sulfite pulping is: H2SO3 +Ca(HSO3)2, pH = 1.

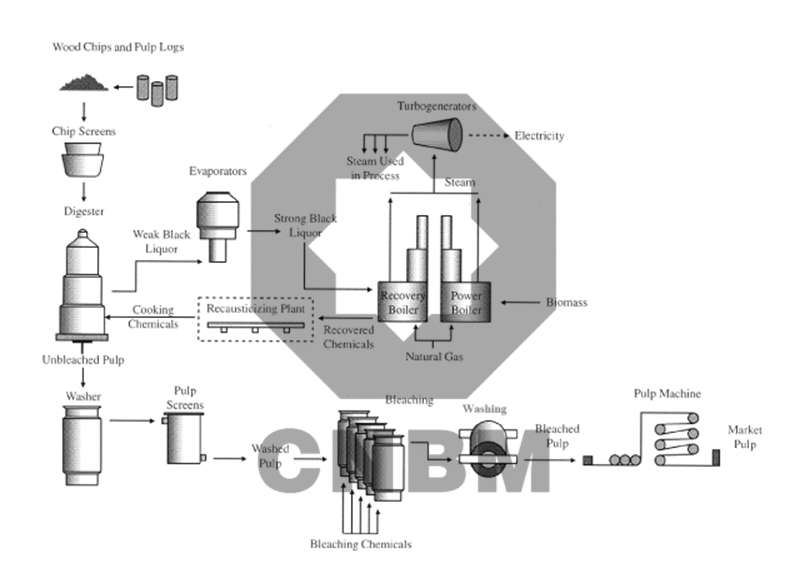

Chemical paper pulping process

Among the various paper pulping methods, the chemical method accounts for a large proportion, while in the chemical method, the alkali method is the main one. Most straw pulps are produced by caustic soda method (or by adding a small amount of AQ), while chemical pulp is produced mainly by Kraft process, especially with the development of multi-stage bleaching, the color of Kraft pulp is resolved. The problem of hard bleaching and the improvement of alkali recovery technology solve the problem of black liquor pollution, so alkali pulping is widely used.

The following mainly introduces the alkali cooking process of chemical paper pulp:

Chemical paper pulp equipment

The equipment needed for chemical pulp is similar to the production process of Kraft wood pulp, which mainly includes: chip bin, cooking pot, spray pot, vibrating frame type flat screen, vacuum pulping machine, black liquor tank, black liquor metering tank, white liquor metering tank, heat recovery system, etc. Alkali recovery system, paper pulp pool, etc.

According to different cooking methods, alkaline cooking can be divided into intermittent cooking and continuous cooking. The equipment and operation process of different cooking methods are different. The intermittent cooking equipment has steam balls and vertical cookers, and the continuous cooking system includes vertical cooking. Horizontal pipe type and inclined pipe type are also used in continuous steam system.

What kind of paper can be made of chemical pulp

The use of chemical pulp depends on the type of raw materials, cooking methods and product quality indicators. According to the type of raw material and pulping method, chemical pulp can make different paper products.

Bleached chemical pulp is mainly used for high grade printing paper, copy paper, computer paper, offset paper, cover paper, writing paper and bag paper; unbleached chemical pulp is used for high strength industrial paper such as Kraft paper, bag paper, etc.

Sulfite wood pulp, clean and soft, easy to bleach, can be used to copy advanced writing paper and printing paper; Kraft wood pulp, fiber thin, strong and tough, can be used in manufacturing industrial paper, etc.

The details are as follows.

Cooking methods:

- Kraft pulp: paper with high production strength, such as noodle board, bag paper, wrapping paper.

- Bleached Kraft pulp: high-grade book paper, offset paper, etc.

- Sulphite pulp: cellophane, greaseproof paper, paper covers, wrapping paper, letterpress printing paper.

- Bleached sulfite pulp: writing paper, offset paper, watercolor paper, dictionary paper, etc.

Raw materials:

- Coniferous pulp: used for high strength paper.

- Broad-leaved wood pulp: bleached pulp used for various printing paper.

- Straw pulp: general cultural paper.

CNBM is one of the leading paper pulp machine manufacturers in the field of paper pulp machinery. Our company's leading products include large chemical containers, tower, reactor, heat exchanger, complete pulping production line, intermittent cooking equipment, large-scale chemical pulp production line, complete set of chemical paper pulp production line, multi-disc vacuum filter and other complete sets of paper pulp machines. Welcome friends from all over the world to contact us!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.