How to Make Paper Pulp

Pulp is made from some plants, and plant fiber is the basic raw material of paper making. Generally speaking, plants used as pulping materials can be divided into four categories: stem fiber, phloem fiber, seed wool fiber and wood fiber. In particular, wood fibers are the most important. The process of making pulp is the process of separating the fiber from the raw material of plant fiber and getting the pulp.

What are the ways to make paper pulp

There are three main methods for making paper pulp: chemical, mechanical, semi-chemical or chemical-mechanical processes, which make the raw material of plant fiber dissociate into raw color or bleached pulp.

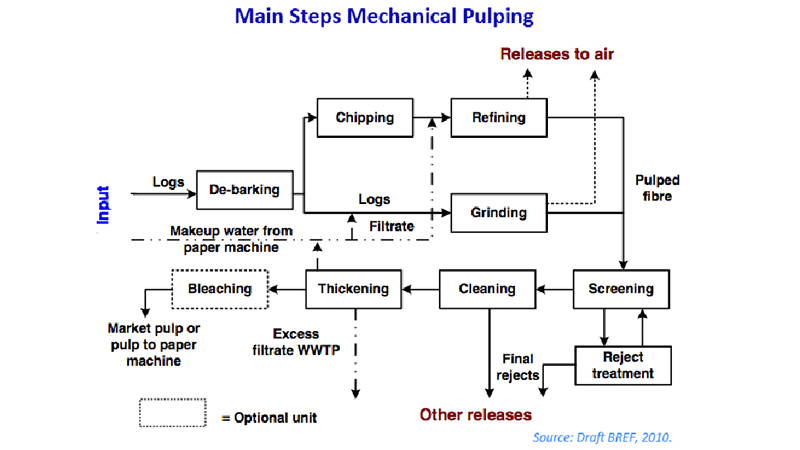

Mechanical method paper pulp

Mechanical method refers to the pulp made of fiber by friction, shearing, tearing, cutting and so on. This is a physical process in which plant fiber materials are dispersed into fibers without the use of any chemicals. The paper pulp made by this method is called mechanical pulp. It plays an important role in the paper industry. It has low production cost and simple production process. The ink absorption of this kind of paper is strong, opacity is high, paper is soft and smooth. It is suitable for printing.

However, the strength of paper is low because of short fiber and high content of non-cellulose components. In addition, because most of the lignin and other non-cellulose in the wood have not been removed, the paper produced by mechanical method is easy to get yellow and brittle and can not be preserved for a long time.

Usually, mechanical pulp consists of white mechanical pulp and /pown mechanical pulp. White mechanical wood pulp is mainly used to produce newsprint, and can also be mixed with other pulp to make copy writing paper and printing paper. /pown mechanical wood pulp is used to produce wrapping paper and paperboard, especially for industrial use.

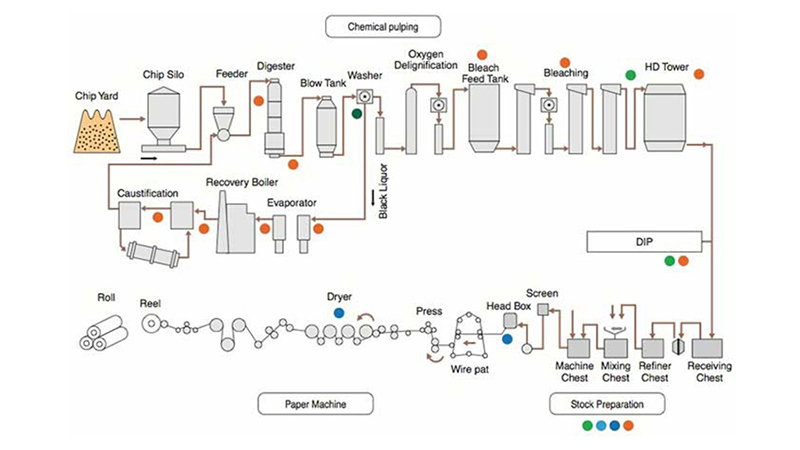

Chemical method paper pulp

Chemical method is a pulping process in which chemical chemicals react with lignin in the tablets at high temperature to separate and disperse the fibers into pulp. Chemical method is mainly divided into alkali method and acid method, and also includes lime method, caustic soda method. Chemical pulp is mainly divided into Kraft pulp and sulfite pulp.

Alkali method (mainly introduce sulphate method)

Kraft pulps are called Kraft pulps by using sodium hydroxide and sodium sulfide mixture as cooking agent. In the cooking process of alkaline pulping, the action of medicinal liquid is relatively gentle, the fiber is not strongly eroded, so the paper is strong and tough. Kraft pulp made of paper, its folding resistance, breaking resistance and tear strength is excellent. Kraft pulp made of paper can generally be divided into two kinds, bleached and unbleached. Unbleached Kraft pulp can be used to make Kraft paper, bag paper, Kraft carton board and general wrapping paper and paperboard. Bleached Kraft pulp can be used to produce high-grade printing paper, drawing newspaper, offset paper and writing paper.

Acid method (mainly sulfite method)

Sulfite method is a pulping method in which the mixture of sulfite and acid sulfite is used as the raw material of cooking agent. The pulp is called sulfite pulp. The pulp has long fiber, soft properties, good toughness, high strength, easy bleaching and excellent in interweaving ability. According to its degree of refinement, it can be divided into unbleached, semi-bleached and bleached.

The unbleached pulp is yellow because it contains a small amount of lignin and colored impurities. It is usually used to make medium printing paper, thin wrapping paper, translucent paper and oil-proof paper. Semi-bleached pulp contains a large amount of pentose, which is used to make transparent tracing paper and parchment imitation paper. The fiber of bleached pulp is white, pure and soft, but the strength of bleached pulp is lower than that of unbleached pulp. The pulp is used to produce a variety of advanced paper.

Semi-chemical method paper pulp

Semi-chemical method refers to the raw material after proper pre-cooking, and then tear up. It is commonly used to bleach BCTMP pulp, which has the advantages of mechanical pulp and chemical pulp.

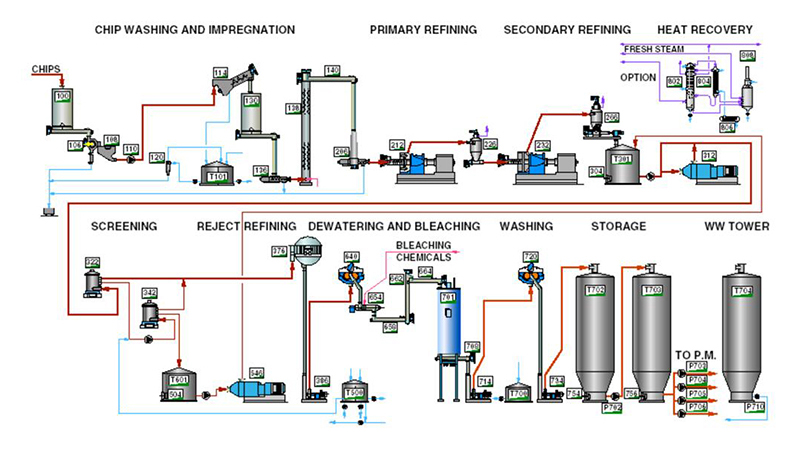

Chemical mechanical method paper pulp

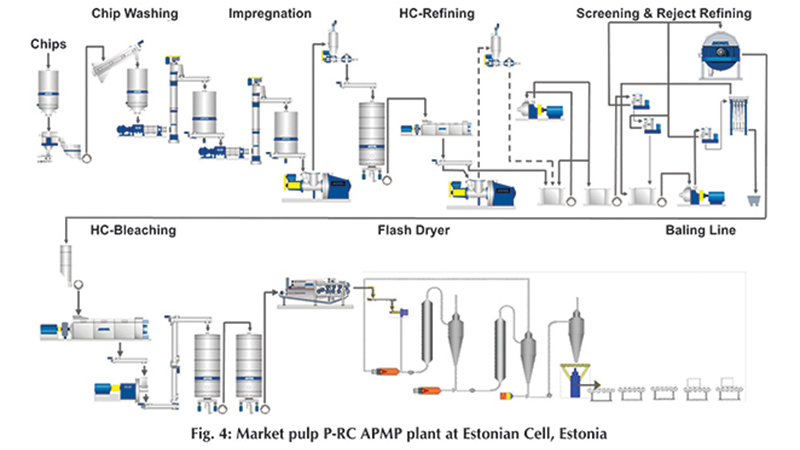

Chemical mechanical method is a combination of chemical and mechanical methods. It uses a mild chemical process to treat raw materials and then grind them into pulp. It is characterized by two-stage pulping, including two stages of chemical pretreatment and mechanical post-treatment.

Chemical pretreatment (I. e., impregnation) is a chemical agent to dissolve the non-fiber components of the raw materials, to achieve fiber softening, making the fiber tissue relaxed, more suitable for pulp grinding. One of the most famous is the APMP process, the pulp is called APMP alkaline hydrogen peroxide chemical mechanical pulp. The APMP process combines pulping and bleaching at the same time. Its technological process is mainly impregnation and pulp grinding. The degree of chemical treatment in the chemical mechanical method is much more moderate than that in the semi-chemical method.

CNBM provides clients all over the world with all sets of paper pulper machines and turnkey paper pulping project. View our products for more information and leave messages to get in touch. Contact us today!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.