How to Make Wood Pulp. Part 1

In this article, we will talk about how to make wood paper pulp. Some people may say that the articles on an enterprise website is of course for product promotion, but think about it, these articles are mainly write by engineers on the front line. The experience extracted in their concrete practice has its particular value. This topic will be talk in two parts. In this first part, I will explain what is paper pulp and what kind of wood is suitable for making wood pulp. In the second part, we will get to know the process of making wood paper pulp and which paper pulper machine is essential in each process.

What is paper pulp

Pulp or paper pulp is a kind of fibrous substance made from plant fiber by different processing methods. It can be divided into mechanical pulp, chemical pulp and chem-mechanical pulp by processing method. It can also be divided into wood pulp, grass pulp, hemp pulp, reed pulp, sugarcane pulp, bamboo pulp and rag pulp etc by raw materials. It can also be divided into refined pulp, bleached pulp, unbleached pulp, high yield pulp and semi-chemical pulp etc by different purity. Ordinary pulp usually used to make paper and cardboard. Refined pulp is often used to make specialty paper.

What kinds of wood is suitable for making paper pulp

Pulpwood is wood that was cut and used to make wood pulp and paper. We will introduce commonly used coniferous wood and broadleaf wood in paper pulping process.

- Pulpwood can be divided into two categories according to plant classification. Gymnosperms are commonly referred to as cork or coniferous wood. The angiosperms are called hardwood, broadleaf wood, deciduous wood or evergreen wood.

-

The coniferous wood has compact structure, contains a lot of lignin, and most of the lignin is distributed in the cell wall, which make this kind of wood is difficult to digest. As for the broadleaf wood, the structure is more impact than coniferous wood, so it is not easy to soakage. But compared with coniferous wood, broad leaf wood contains less lignin, and the lignin is not mainly distributed in the cell wall, so it is easier to digest.

- Pulpwood can be different in physical properties and chemical composition because of their different variety and structure, because of which the cooking condition and the pulp properties will be different, too. Even they are the same kind of tree, it is hard to avoid the difference because of their different sapwood, ratio of core material, latewood percentage and material origin. Hardwood usually contains more synthetic fiber and less lignin than softwood, and the extract material content is higher.

- Common coniferous pulpwood materials are Scandinavia pine, radiation pine, southern pine, redwood, lodgepole pine, cedar, hemlock, white spruce, black cedar, Douglas fir, larch, balsam international and mountain fir etc.

- Radiation pine and southern pine is usually used to making paper pulp in America, Chile and New Zealand. Scandinavia pine is usually used to make paper pulp in Nordic countries. The other trees are common tree species in Canada. In north American tree species, the extract content of dried wood is less than 1%, and the extraction content of southern pine is slightly higher.

-

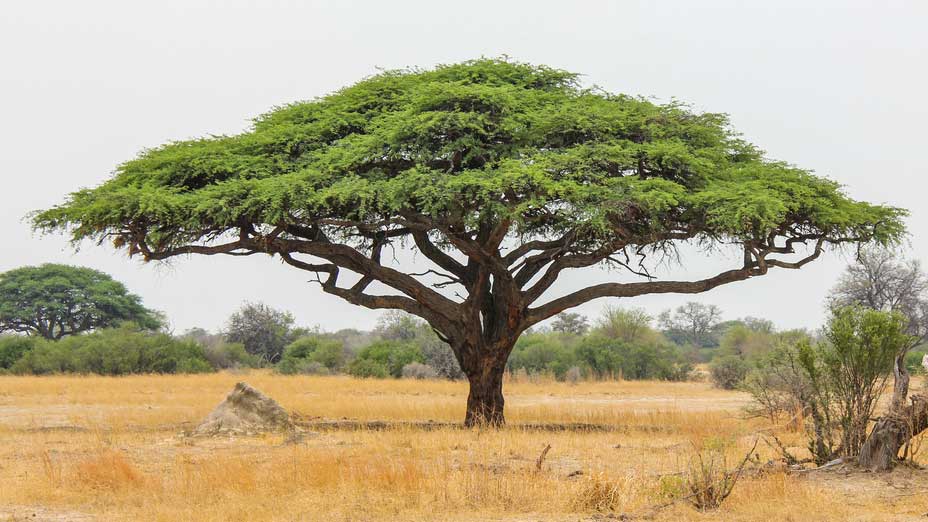

Common broadleaf pulpwood materials are: press wood, acacia wood, poplar, birch, maple, etc.

- Eucalyptus has many varieties, such as eucalyptus grandis, eucalyptus urophylla, eucalyptus globulus, Lemon eucalyptus, meranti, eucalyptus exserta, eucalyptus camaldulensis, etc. Some eucalyptus are not suitable for making paper according to the wood (for example, eucalyptus exserta) is not suitable for paper making, and the high proportion eucalyptus is not suitable for paper making, generally speaking, the proportion lower than 0.7 eucalyptus is the best choice. Eucalyptus BEK are different in quality, so it is necessary to know the BEK is made of which kind of eucalyptus. Generally, Brazil BEK is mainly made from the eucalyptus grandis, Chile and Spain are mainly eucalyptus globulus. In China, guangxi liujiang paper factory and plastic paper company produce a certain amount of goods BEK, and the raw materials are lemon eucalyptus and eucalyptus grandis. Because there are so many kind of eucalyptus, and according to the climate and regional difference, the price can be different, too. In general, the Brazilian eucalyptus is most quality, while the Southeast Asia eucalyptus has the poorest quality. But all depends on the concrete purpose.

-

Acacia wood (also called acacia wood), as a kind of special researching and developing pulpwood, is no worse than tropical wood effect in fast-growing and high-yield, especially suitable for artificial cultivation in South-east Asia climate. In recent years, with the rapid growth of production, it has gradually become an important option in the market. As for price, its representative brand lovesick has been neck-and-neck with Brazil eucalyptus.

- Natural broadleaf forest are hardwood forest including poplar, birch, maple etc. Most of the paper pulp making factories cut the hardwood forest first then plant the man-made forest. The natural forest won't grow back again by itself. So the natural forests are tend to decrease. Because cutting down natural hardwoods are not friendly to environment, the hardwood forest cutting factories have got very bad reputation. In the long run, the hardwood paper pulp may disappear. Now about 20% paper pulp is made from hardwood. The other 80% is made from softwood.

In a word, there are a lot of wood can be made into paper pulp. And CNBM can provide the proper paper pulper machines for all kinds of raw materials. The pulping process and the products needed will be posted in the next article. Leave messages for quotation and details, contact us now!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.