Paper Pulping Problems Should be Noted

There are some problems to be paid attention to in paper pulp making with different methods. The pulping requires that the plant fiber be separated into monomeric fibers with less or no damage to the fiber, so that the pulp has a certain specific surface area and interwoven properties, creating conditions for the re-binding of the fibers. The basic process of pulping includes preparation, pulping, washing, screening, bleaching and pulping.

In the pulping process, different methods should pay attention to different problems.

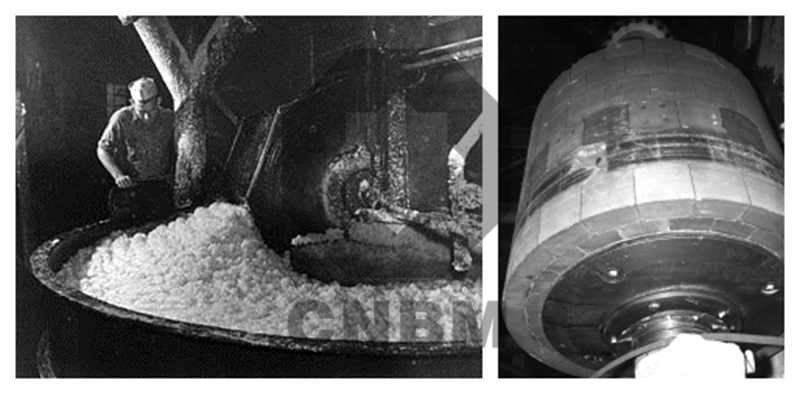

Mechanical pulping

Raw material status

Water should be kept at 40-45%. When the moisture content of the raw material is less than 20-30%, the yield and quality of the pulp will decrease and the power consumption will increase. When the moisture content of the raw material is more than 50%, the pulp yield decreases.

Grinding stone condition

When the grain front of the grinding stone is sharp, the pulp yield is high and the unit electricity consumption is low. But grinding stone to cut the main role, grinding out of the fiber short hard, more debris. When the grain front of the grinding stone is completely blunt, the pulp output decreases and the electricity consumption increases. At this time, the grinding stone needs to be replaced.

Operation condition

The specific pressure increases: the output increases, the coarse fiber increases, the pulp strength drops.

Chemical pulping

The amount of medicine used.

Effect of cooking temperature and time.

Semi-chemical pulping

The grinding conditions should be adjusted and controlled according to the production requirements.

The degree of dissociation and fine fibrosis should be controlled according to pulp use.

Type, size, cooking method and degree of pulp raw materials and requirements for making.

Attention should be paid to the prevention of washing , dehydration difficulties and clogging of the grinding holes caused by the occurrence of adhesion of the pulp .

Chemical mechanical pulping

Effect of pre-processing time

The pretreatment time is too short and the impregnation is incomplete. When the pretreatment time is too long, the pulp yield decreases and the optical properties decrease.

Effect of pretreatment temperature

The pulp material can be fully softened at higher temperature, which is beneficial to the soaking of the liquid and the swelling of the fiber.

Effect of chemical dosage

Appropriate chelating agents and protective agents should be added at high temperature to control and reduce the thermal decomposition of hydrogen peroxide.

Influence of Grinding conditions

The quality of pulp is affected by many factors, including feed speed, pulp concentration, disc clearance and so on. Increasing the number of pulp sections can improve the quality of pulp, but will increase the energy consumption and equipment investment. Disc mill clearance should not be too small, otherwise pulp whiteness and strength will be affected.

Equipment required for different methods of paper pulping

Influence of Grinding conditions

Wood grinder, coarse sieve, coarse sieve pulp slot, first sieve, first sieve, thickener, thickener, dehydrator, disc mill, second sieve, second sieve, bleach tower, shredder, shredder pulp trough, pulp slag trough, recovery system and so on.

Chemical paper pulping machines

Spiral preheater, cooking pan (or steam ball, continuous steam system, spray bin, vi/pating frame screen, pulping machine, vacuum pulping machine, black liquor tank, white liquid tank, recovery system, causticizer, digester, etc. Different styles of equipment should be adopted for different methods.

Semi-chemical paper pulping machines

Disc mill.

Chemical mechanical paper pulping machines

Wood Warehouse, Pre-Dewatering Spiral, Atmospheric pressure-Presteam Warehouse, diffuser, Scrubber, Spiral tearing Machine, Impregnator, reaction Warehouse, submerged Tank, filtrate Tank, seam screen, filter Press, High consistency pulp Storage Tower, etc.

CNBM can design and engineer paper pulp production line according to your requirement and we can also provide all the paper pulping machines you may need including digester, blow tank, replacement tank, heat exchanger, all kinds of supporting tank like cold and hot black liquor tank, cold and hot white tank, etc. and other auxiliary valves etc. Our professional engineer can make customized plan for you and meet your process demands and local environment protection standards precisely. Please leave us messages below to get a quote and more details. Contact us, today!

Leave messages for quotations and solutions. The average response time is up to 24 hours. Your privacy is protected. Check privacy policy here.